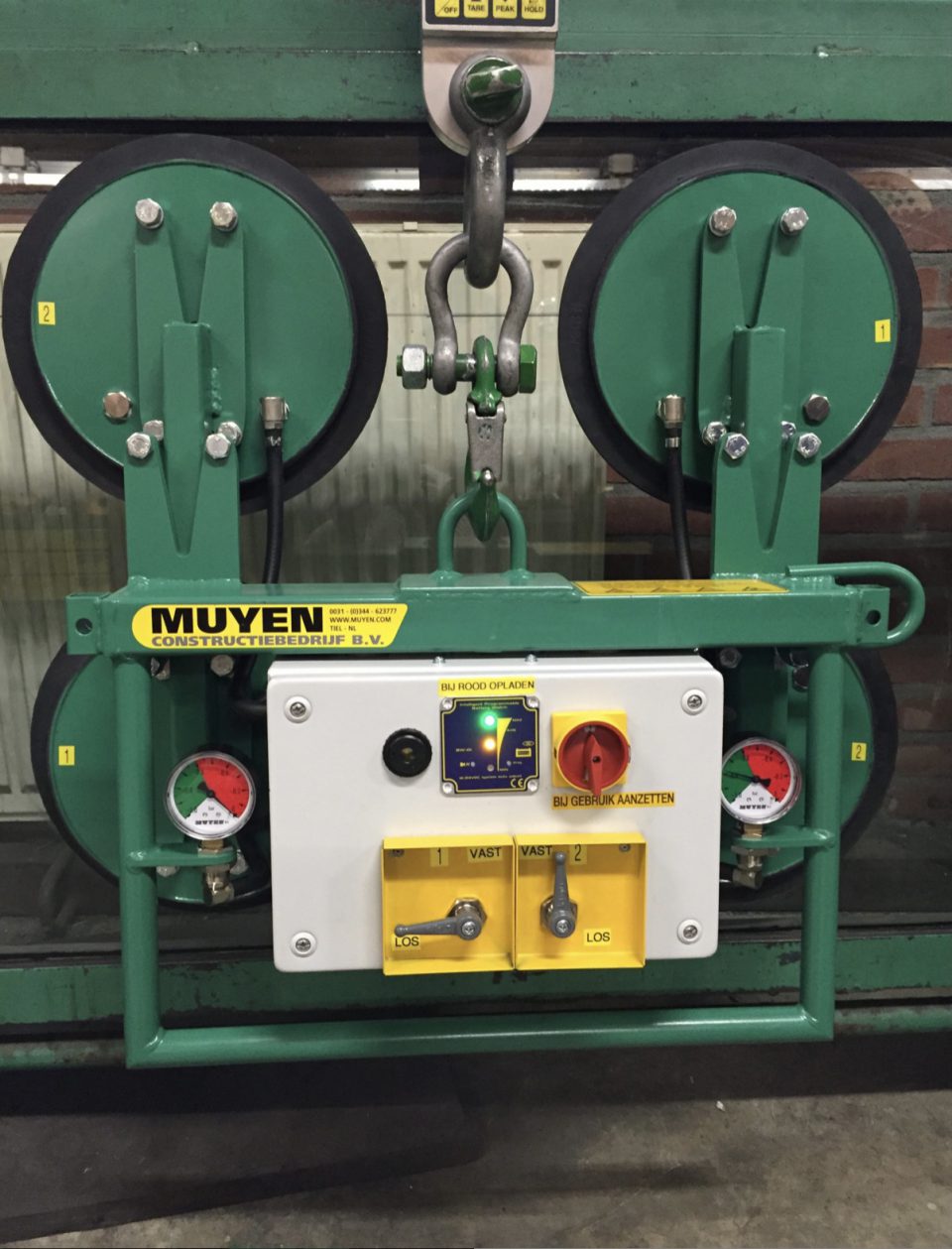

Request The MUYEN vacuum safety ladder, safety S2.

Specifications

- Category Glass trolleys, GlassLifting

Description

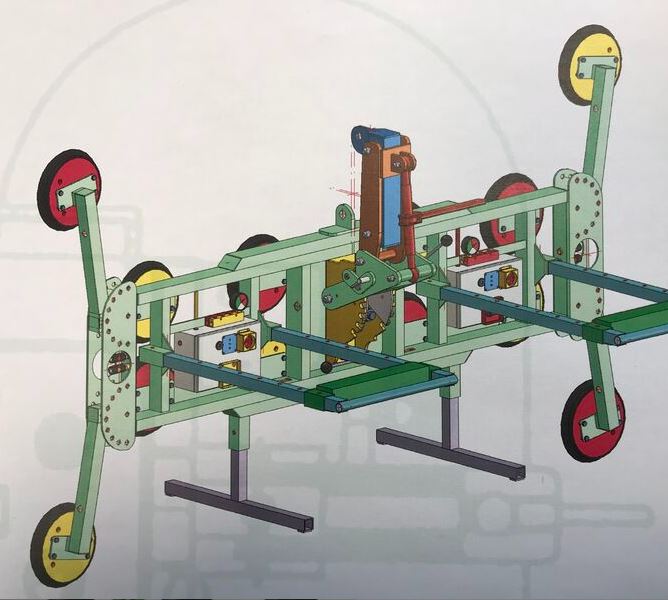

Technical description off the vacuum lifting device:

- The vacuum lifter works with hand cautions cups and you always use a fall protection above 1.8 meters.

- The vacuum lifter is battery operated with a single system with a large tank giving you more buffer and a longer warning alarm, 1 pump and battery.

- The vacuum lifter works on battery with a double system with 2 small tanks, with alarm, 1 pump and a battery.

- Use a fall protection if there is a risk off falling load due to impact, breaking or sliding or the risk of persons under the load.

Examples of tools: hoisting trolleys, aluminium Gevelridder, mini cranes, manual vacuum lifters or battery operated lifters with alarm, single or double system. If you cannot reach the vacuum device to release the glass plate, use a radio control.

Note:

- a vacuum lifting device never makes a permanent connection with the load. Contrary to what is stated in the European standard 13155, you must therefore always use a fall protection if there is a danger of falling load, so also when using a double vacuum system. See also the statement from TUV about this.

- the double safety system S2 is entirely in accordance with the description of the European standard 13155. It is always possible that construction management, clients or KAM coordinators have different requirements, they have this right as your client, you cannot anticipate this, but many clients and KAM coordinators have already embraced this vacuum safety ladder.

- If you cannot reach the vacuum device to release the glass plate, use a radiographic control.

- Always use the correct personal protective equipment, such as the right shoes, helmet, gloves, but also clothing made of cut-resistant material.

- Maintain your lifting device in the right way, regular cleaning and testing according to the manual, 1x per year maintenance and inspection by the supplier. It is important here that a pull test is carried out at least once a year in a vertical position with 2x the maximum lifting weight.

- you place your hands safely so that you cannot get caught, you keep the workspace clean so that you cannot fall and you lift the glass plate ergonomically or you use lifters.

- Turning larger glass plates (tops, 90 degrees like the blades of the mill) is always done as safely as possible, on the ground floor, you are outside the fall area when turning, you use a wooden angle block or ground plate on the ground supporting the glass plate during tilting.

NL: